Why use Polyurethane?

Polyurethane elastomers are a very unique material that offers the elasticity of rubber combined with the toughness and durability of metals. Elastomers can be manufactured in a variety of hardness’ from soft like rubber to hard like a bowling ball or any hardness in-between.

Due to the versatility of polyurethane elastomers, the range of components that can be manufactured with these systems are vast. Parts made from polyurethane elastomers have been proven to outwear a number of other materials. It is largely superior to materials like rubber, plastics and even metals in some applications.

Polyurethane Elastomers are Abrasion Resistant, Dry Heat Resistant, Oxygen & Ozone Resistant, Water Resistant, Oil Grease & Chemical Resistant, Radiation Resistant, Flame Resistant, Mould, Mildew, Fungus Resistant.

Elastomers are used throughout a wide range of Industries including the Concrete Industry, Building, Prototyping and Mining Industries to name a few.

What are the benefits of Elastomers vs Rubber?

– High Abrasion Resistance

– High Cut & Tear Resistance

– Superior Load Bearing

– Thick Section Moulding

– Colourability

– Oil Resistance

– Ozone Resistance

– Radiation Resistance

– Castable Nature

– Broader Hardness Range

What are the benefits of Elastomers vs Plastic?

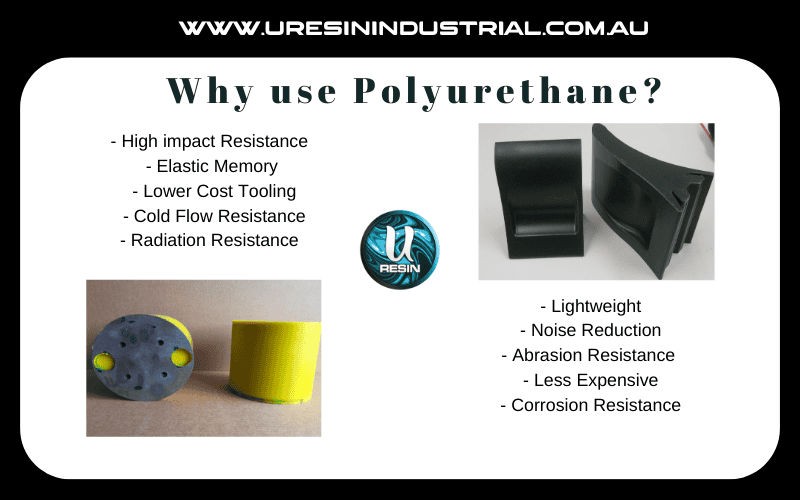

– High impact Resistance

– Elastic Memory

– Abrasion Resistance

– Noise Reduction

– Radiation Resistance

– Thick Section Moulding

– Lower Cost Tooling

– Cold Flow Resistance

– Low Temperature Resistance

– Drag Resilience

What are the benefits of Elastomers vs Metal?

– Lightweight

– Noise Reduction

– Abrasion Resistance

– Impact Resistance

– Flexibility

– Non Conductive

– Range Easy Mouldable

– Non Sparking

– Less Expensive

– Corrosion Resistance

If you have a project in mind or components being made from an inferior product that you would like to change, be sure to contact our team. We will be able to assist you with the best product specifications for your project needs.