Difference between Shore A and D Hardness

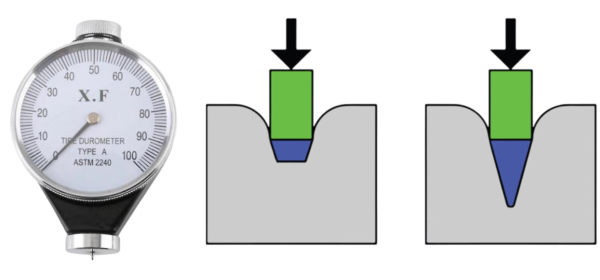

Difference between Shore A and D Hardness – Polyurethanes are versatile and widely used materials in many industries. They are known for their durability, strength, and elasticity. Polyurethanes come in various forms and are classified based on their hardness. Shore A and Shore D are two common measurements used to determine the hardness of polyurethanes. Both measurements use a durometer, which is a device that determines the indentation hardness of materials.

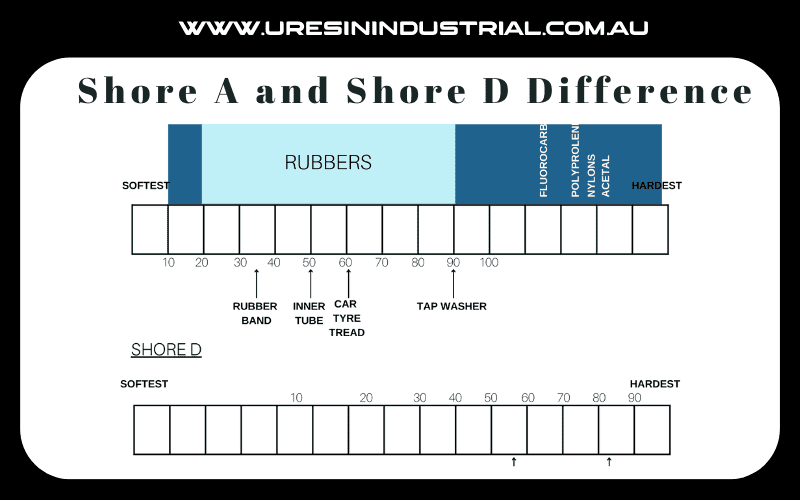

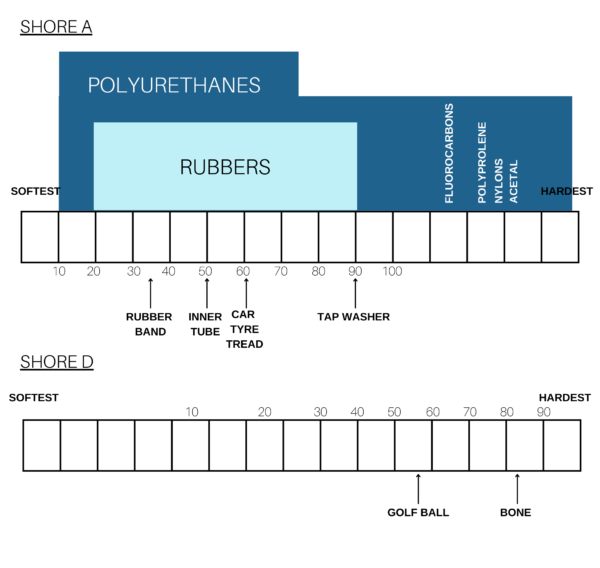

Shore hardness is a measure of the resistance of a material to indentation. Shore A measures the hardness of materials that are more flexible, such as rubber, while Shore D measures the hardness of more rigid materials like plastics. Shore A and Shore D hardness measurements are crucial in selecting the right polyurethane material for different applications.

Shore A Polyurethanes –

Shore A polyurethanes are materials that have a hardness range of 0 to 100 on the Shore A scale. They are soft and flexible, making them ideal for applications where the material needs to be able to bend or compress. These materials are commonly used in industries such as footwear, medical equipment, and automotive parts.

A Shore A value of 0 indicates that the material is very soft, while a value of 100 indicates that the material is very hard. Shore A polyurethanes are commonly used in applications where the material needs to have a certain degree of flexibility, such as in the production of foam rubber, gaskets, and seals.

Shore D Polyurethanes –

Shore D polyurethanes have a hardness range of 0 to 100 on the Shore D scale. These materials are more rigid and less flexible than Shore A polyurethanes. They are used in applications where the material needs to have a higher degree of stiffness and strength, such as in the production of wheels, gears, and conveyor belts.

A Shore D value of 0 indicates that the material is very soft, while a value of 100 indicates that the material is very hard. Shore D polyurethanes are commonly used in applications where the material needs to have a higher degree of strength and stiffness.

When choosing the right polyurethane material for your application, it is crucial to understand the difference between Shore A and Shore D. This will ensure that you select the right material with the correct hardness for your specific application.

For example, if you are producing a conveyor roller that needs to be strong and rigid, you would choose a Shore D polyurethane. If you are producing a gasket that needs to be flexible, you would choose a Shore A polyurethane.

It is important to select the right material with the correct hardness for your specific application to ensure the best performance. At U RESIN, we offer a wide range of polyurethane products that are perfect for different applications. Whether you need Shore A or Shore D polyurethane, we have you covered. Our team of experts can help you choose the right material for your application. Contact us today to learn more.